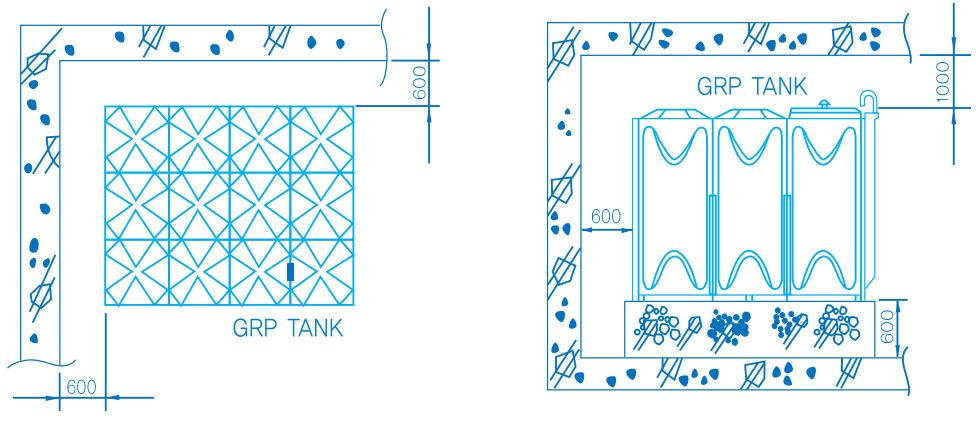

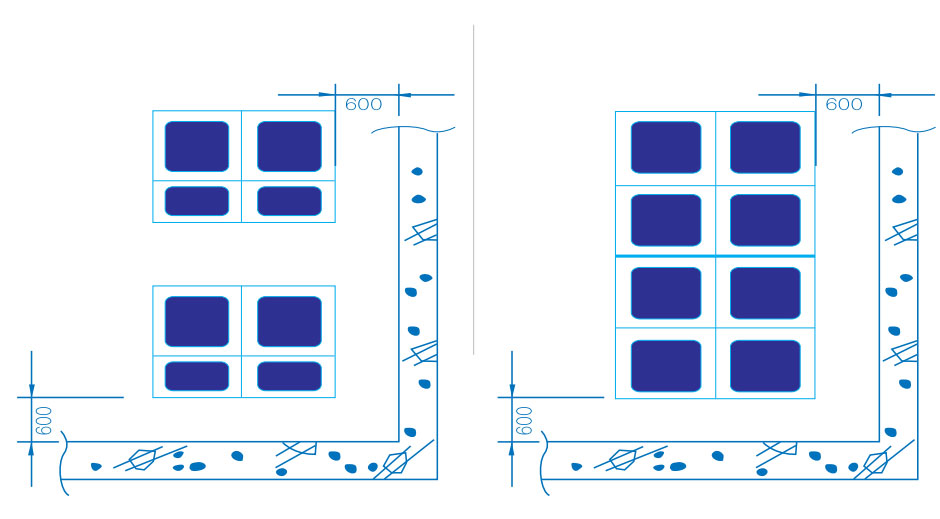

Installation Space

A space for 600mm apart from the walls in four directions (1000mm for the upper part) is required for the installation of a tank and for its inspection & maintenance.

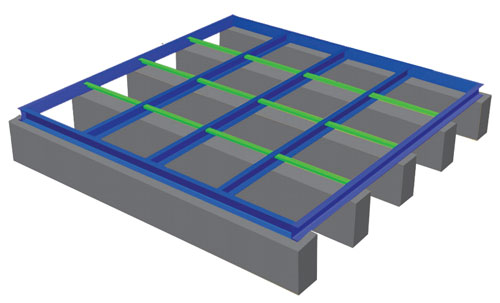

Skid Base

MULTANK reserves the right to provide alternate skid base designs. We recommend and

ideal concrete plinth size of 400mm (W) x 475mm (H) with maximum variance in height of

not more than 2mm.

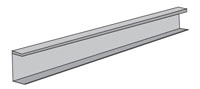

External Base frame designed to BS729 HDG and the specification for materials used by

tank specification is:

| Tank Height | Main Frame | Sub Frame | Design According |

|---|---|---|---|

| 2.5M Below | Angle 75 X 75 X 6t C | Channel 75 X 40 X 5t | BS729 |

| 3.0 m & Above | Channel Frame 125 X 65 X 6t | Channel 75 X 40 X 5t | BS729 |

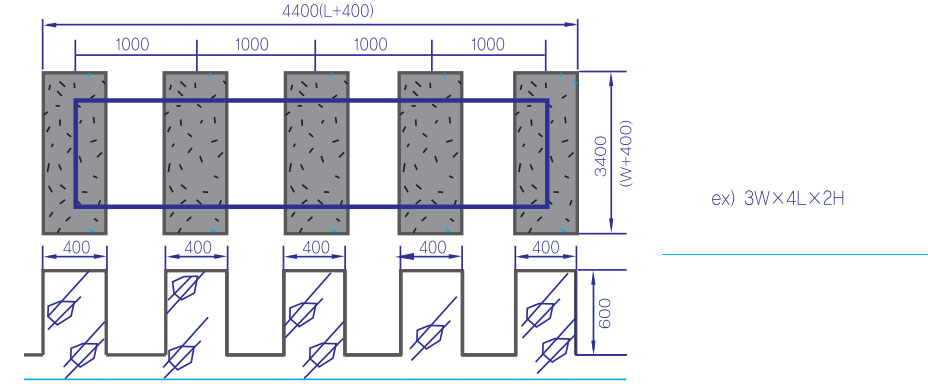

Based on PAD production

WIDTH: More than 400mm

HEIGHT: More than 600mm (Including Base Frame)

INTERVAL DISTANCE: Less than 1m max.

OUTLINE DIMENSION: W,L+400mm

Horizontality Degree: Less than 1/500(Maintains Smoothness at the upper part)

Scope of Construction

Foundation work

Pipe work

Cautions for Handling

Transportation

Take precaution to avoid any partial great force such as an intensified load or shock to the tank. Be sure to put buffering materials on the part where a rope or vehicle contacts.

Piping

Repair and maintenance

Regulations for Installation Criteria for Construction Foundation Work

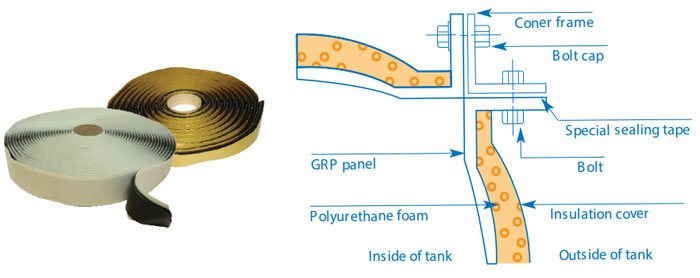

| Saint-Gobain Sealant Tapes have following

features: • Excellent adhesion to a wide range of substrates • Good UV resistance • The foam component allows good compression without squeezing the sealant out of the joint • Good resistance to mild acids and alkalis • Can be repositioned during tank construction if applied foam-side down • Easy and accurate to use with little waste and no mess |

|

|

| Sealing Tape | ||

|

|

|

| Water Level Indicator: | Flanges | Ventilation |

| "MULTANK uses Level Indicator consists with a glass or transparent tube protected with Aluminum case having one safety valve in the bottom. The level indicators are available in all sizes up to 5 meters. | Flanges shall be of upvc type | "The air vents used by MULTANK are ABS material (50mm or 100mm) with PE insects guard |

|

|

|

| Roof Support. | Tie Rod | |

| “Used GRP / FRP which is same material for the panel, contains no rust and does have excellent mechanical strength” | All tie rod is a slender structural unit with PE \mesh coating used as a tie and (in most applications) capable of carrying tensile loads only. | |

|

|

|

| Internal Ladder : FRP/GRP (Optional SS) External LAdder: HDG (Optional SS) | Rubber Head Bolts: SS316/A4, Assembly Bolts: SS304/A2 & 316/A4, Bolts for Skid Base Frames: HDG | |

|

|

|

|

| Anchor Bracket (HDG) | Brass Socket | Wall Bracket (HDG/SS316) | |

|

|

|

|

| Steel Skid Base – Channel HDG | External Mainframe (HDG) | Wall Bracket (HDG/SS316) | Partition Main Frame SS 316 |